The battery management system (BMS) is a key component in electric vehicles for monitoring and managing battery system performance. It helps balance battery power and prevent overcharging and over-discharging, thereby ensuring the safe, reliable and efficient operation of lithium-ion batteries while optimizing the overall efficiency and life of the battery.

There are two types of EV BMS, low voltage (LV) and high voltage (HV). Low voltage battery management systems (LVBMS) are mainly used in two-wheeled and three-wheeled electric vehicles with ≤30V AC and ≤60V DC . High voltage battery management systems (HVBMS) are designed for the battery monitoring needs of four-wheeled electric vehicles (EVs) with ≤600V AC and ≤900V DC or ≤1,000V AC and ≤1,500 V DC , and play a vital role in ensuring the health and safety of the battery, especially during fast charging. By actively monitoring and evaluating the SOC (state of charge), SOH (state of health), and temperature state (SOT) of EV batteries, HVBMS can effectively prevent thermal runaway of the battery and maximize efficiency and performance.

To ensure the safety and high performance of the entire battery system in electric vehicles over its service life, it is crucial to select the right BMS components. It can maximize the range and service life of lithium-ion batteries, allowing automakers to stand out in the fierce market competition.

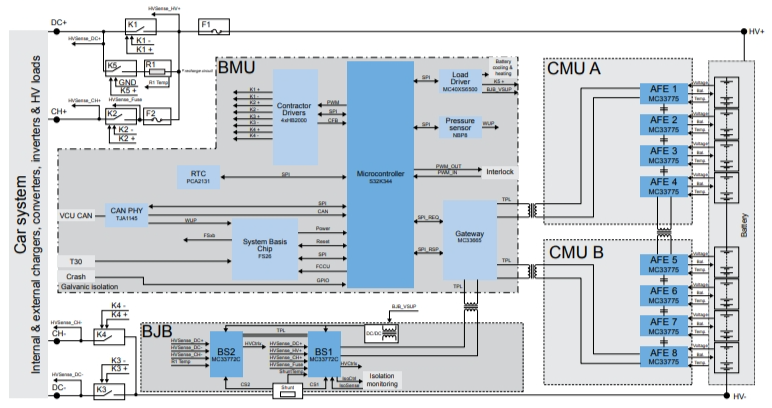

BMS consists of three modules: battery management unit (BMU), battery monitoring unit (CMU) and battery junction box (BJB). How to establish internal communication between BMU, CMU and BJB subsystems, which are the brain of the system, also requires designers to make careful evaluation when selecting a solution.Currently, there are many participants in the electric vehicle battery management system market, which is mainly dominated by several key companies such as Renesas, NXP, Infineon,TI, ADI...

NXP's scalable high-voltage battery management system (HVBMS) reference design includes all three modules: BMU, CMU and BJB.

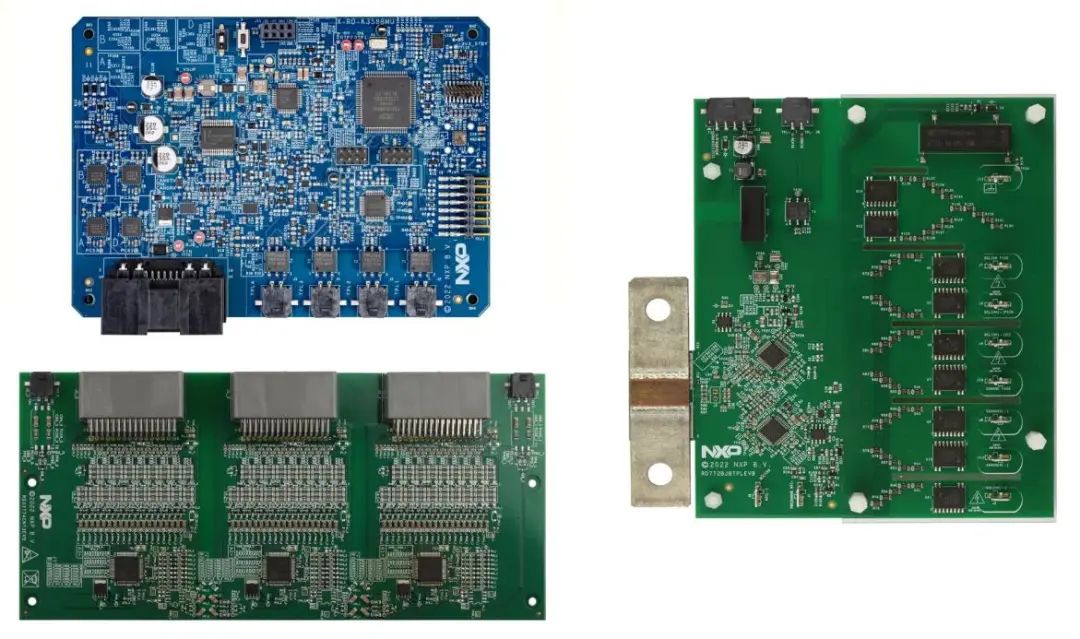

NXP's RD-HVBMSCT800BUN is a reference design kit for an 800V high-voltage battery management system (HVBMS). It provides a complete hardware solution, including the RD-K358 BMU, RD33774CNT3EVB cell monitoring unit (CMU) and RD772BJBTPL8EVB battery junction box (BJB), as well as software drivers and scalable functional safety documentation. Automakers, suppliers and software ecosystem partners can use the kit to directly develop, test and demonstrate.

Specifically segmenting the key components of BMS, the AFE (analog front end) market will grow from US$930 million in 2022 to US$2.24 billion in 2028, themicro-controller market will grow from US$580 million in 2020 to US$1.34 billion in 2028, and the market for various sensors including temperature, current, pressure, acceleration, etc. will grow from US$1.46 billion in 2022 to US$3.5 billion in 2028. (Source:Mouser)